In industrial settings, controlling airflow with precision is essential for maintaining optimal performance, energy efficiency, and safety. One of the most reliable components used to manage airflow in HVAC systems is the Butterfly Damper Valve. Known for its compact design and responsive operation, this valve plays a key role in industries such as power generation, cement manufacturing, steel processing, and chemical plants.

What Is a Butterfly Damper Valve?

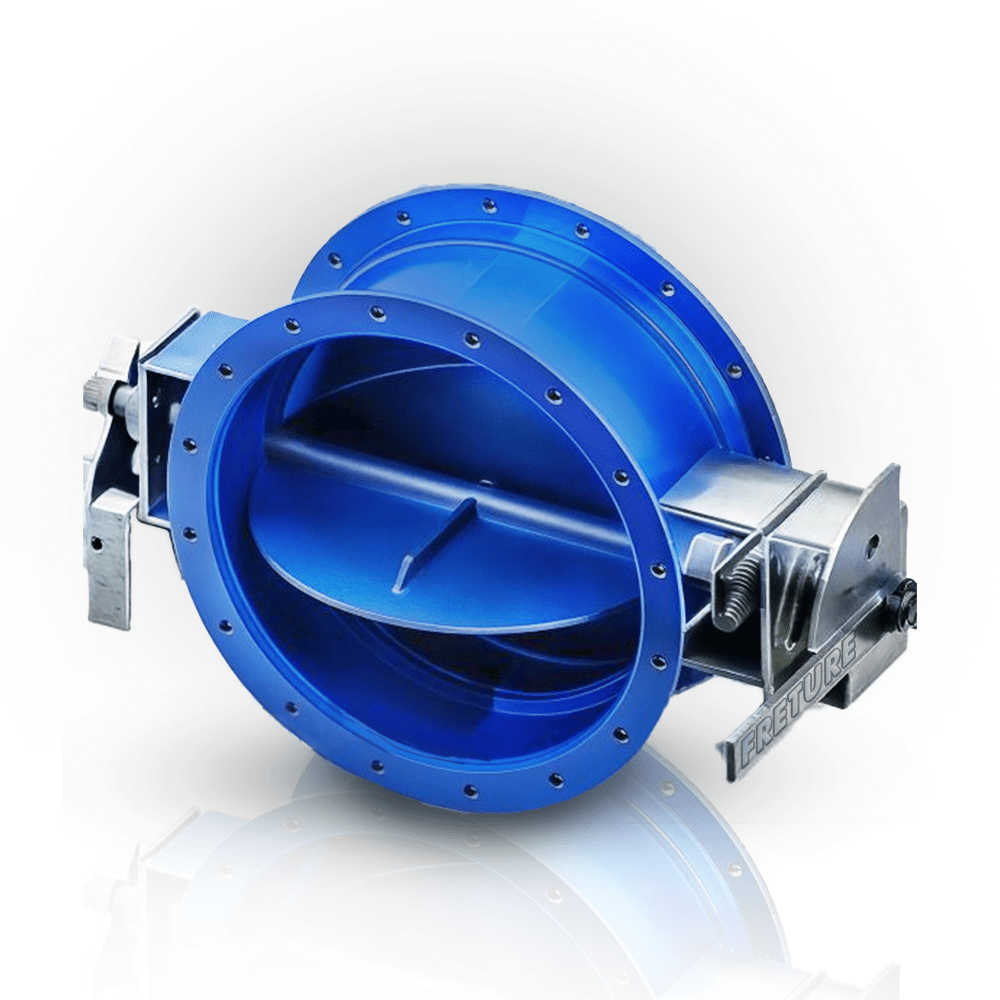

It is a type of flow control device designed to regulate or isolate airflow in ductwork or piping systems. It consists of a circular disc mounted on a rotating shaft. When the shaft turns, the disc rotates to either block, partially allow, or fully permit the flow of air. Unlike traditional valves, these Butterfly Dampers valves are lighter, quicker to operate, and require less space.

|

| Butterfly Damper Valves Manufacturer in Mumbai |

These features make them an ideal choice in systems where rapid and frequent flow adjustments are necessary.

Importance in Industrial HVAC Systems

Industrial HVAC systems require a careful balance between air distribution and energy consumption. Whether it's managing exhaust gases in a power plant or controlling ventilation in a large manufacturing facility, these Damper Valves provide a flexible and efficient solution.

Here’s how they enhance airflow control:

1. Efficient Modulation of Airflow

The Dampers allow for precise modulation of airflow. The valve disc can be set at various angles, enabling operators to finely control how much air passes through a duct. This level of adjustability helps to maintain desired temperatures, improve indoor air quality, and ensure even air distribution throughout the facility.

2. Fast Operation with Low Torque Requirements

Because of their streamlined design, the Damper valves require minimal torque to operate. This means that even large valves can be quickly opened or closed using relatively small actuators. In time-sensitive environments, such quick responsiveness ensures timely adjustments to airflow without delays.

3. Energy Efficiency

In energy-intensive industries, every watt counts. Poor airflow regulation can lead to excessive load on heating, ventilation, and cooling units. These Dampers help avoid this by minimizing leakage and ensuring that airflow is only delivered where needed. By doing so, they contribute to significant energy savings over time.

4. Low Maintenance and Long Service Life

Thanks to their simple construction and fewer moving parts, these Damper valves typically demand less maintenance than other types of valves. Many are designed with robust materials like stainless steel or coated carbon steel, making them resistant to corrosion and wear. This translates into lower downtime and maintenance costs.

Applications Across Industries

While primarily used in industrial HVAC systems, these valves also find applications in:

-

Boiler flue gas control

-

Air pollution control systems

-

Power plant exhaust systems

-

Dust collection units

-

Food processing ventilation

This versatility makes them a preferred solution across multiple sectors.

Choosing the Right Damper Valve

When selecting a the Damper for your system, several factors should be considered:

-

Operating temperature and pressure

-

Type of media (air, gases, particulates)

-

Actuation method (manual, electric, pneumatic)

-

Material of construction

-

Installation space availability

It’s also essential to choose valves that comply with relevant industry standards for leakage, fire safety, and environmental regulations.

Conclusion

In modern industrial HVAC systems, Butterfly Damper valves have emerged as an indispensable component for effective airflow control. Their ability to regulate air with precision, their quick actuation, and their contribution to energy efficiency make them an ideal choice for demanding industrial environments. Whether you're upgrading an existing ventilation system or designing a new one, investing in high-quality Butterfly Damper Valves can lead to better performance, lower costs, and improved system longevity.

If you're looking for durable and efficient Butterfly Damper valves, be sure to choose a manufacturer with a proven track record in industrial valve technology.

No comments:

Post a Comment