In marine and shipboard environments, damper valves play a vital role in maintaining air circulation, temperature control, and system safety. From engine rooms to crew quarters, these valves ensure that airflow is regulated efficiently in both commercial vessels and military ships, even under extreme conditions at sea.

Importance of Damper Valves at Sea

Ships operate as self-contained environments, where air quality, temperature, and ventilation must be carefully managed. Damper valves regulate airflow within ventilation ducts that serve different compartments. This is essential for distributing fresh air, extracting fumes, and maintaining optimal environmental conditions in living areas, machinery spaces, and cargo holds.

They are also critical to emergency response systems. In the event of a fire, smoke, or gas leak, damper valves isolate affected areas by shutting off airflow, preventing the spread of toxic gases or flames.

Types of Damper Valves for Marine Use

Fire Dampers: Automatically close during fire outbreaks to prevent the spread of flames and smoke.

Volume Control Dampers: Adjust airflow to maintain appropriate pressure and ventilation in specific zones.

Backdraft Dampers: Prevent reverse airflow, especially in exhaust systems.

Blast Dampers: Installed in military vessels to withstand sudden pressure surges from explosions.

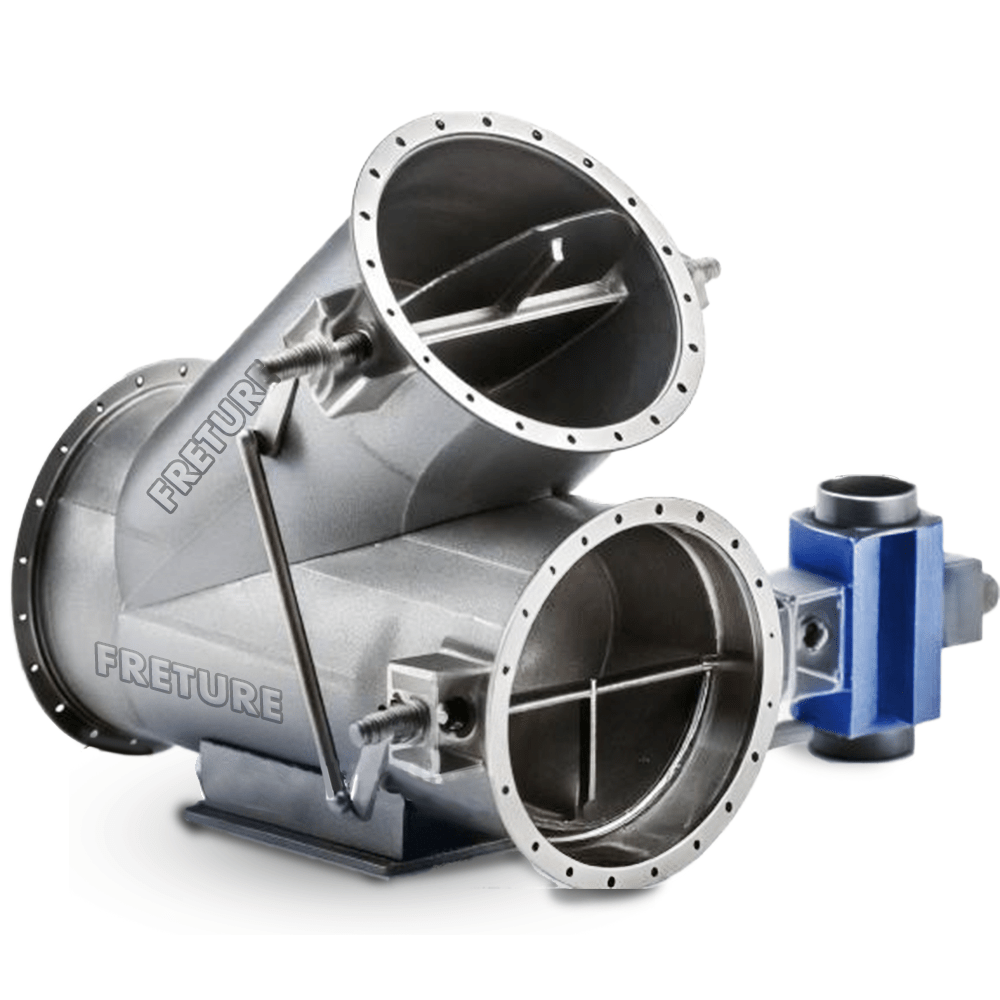

Marine damper valves are constructed with corrosion-resistant materials like stainless steel or coated aluminum to handle salt-laden air and high humidity.

|

| https://pixabay.com/photos/ferry-boat-ship-ocean-ferry-123059/ |

Key Applications Onboard

Engine Rooms: Control ventilation to remove heat and supply fresh air to diesel generators and turbines.

Accommodation Areas: Ensure comfort and air quality in cabins, kitchens, and communal spaces.

Cargo Holds: Maintain airflow and temperature for sensitive or hazardous cargo.

Galley and Sanitary Exhausts: Remove odors and moisture from kitchens and bathrooms.

Naval Applications: Enhance safety by isolating compartments during combat scenarios or emergencies.

Benefits in Marine Operations

Corrosion Resistance: Marine-grade dampers withstand harsh saltwater exposure.

Safety Assurance: Fire and smoke dampers enhance onboard fire prevention and isolation.

Energy Conservation: Reduce the load on HVAC systems by regulating airflow efficiently.

Noise Control: Dampers help minimize duct noise, improving comfort in living spaces.

Compliance with Standards: Align with IMO (International Maritime Organization) and SOLAS (Safety of Life at Sea) regulations.

Maintenance and Operational Considerations

Damper valves onboard ships must undergo regular inspection and testing as part of vessel maintenance. Actuators and sensors should be checked to ensure rapid response in emergencies. Lubrication, seal inspection, and corrosion protection are key elements of routine servicing.

Fire dampers in particular are subject to strict inspection schedules and must meet classification society requirements such as those from DNV, ABS, or Lloyd's Register.

Conclusion

Marine damper valves are critical components of shipboard ventilation, safety, and environmental control systems. Their role in regulating airflow, preventing fire spread, and preserving comfort and functionality makes them indispensable for seafaring operations.

Whether retrofitting existing systems or installing new ventilation setups, selecting high-performance damper valves designed for marine environments ensures long-term safety, efficiency, and compliance on the high seas.

No comments:

Post a Comment