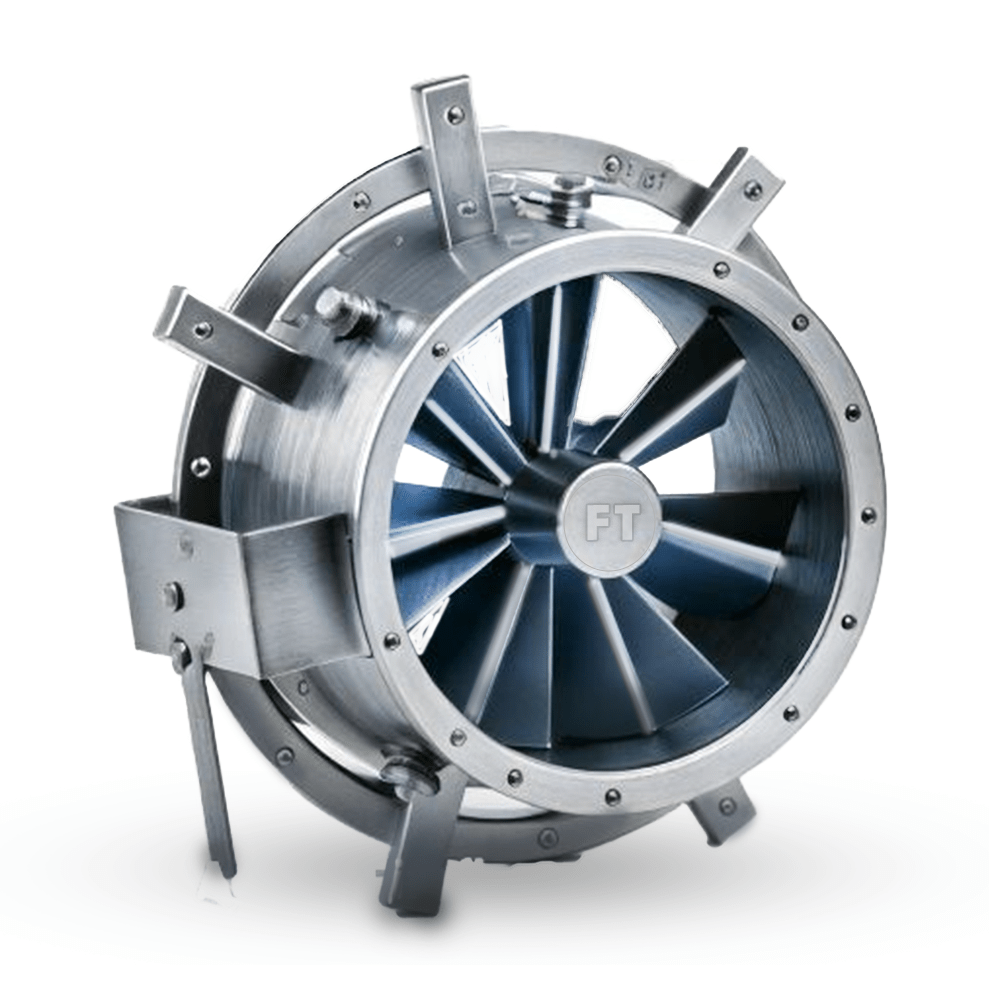

In industrial HVAC systems, optimizing energy consumption is crucial. One effective component that aids in reducing energy costs while maintaining airflow control is the inlet vane damper. These dampers regulate the volume of air entering centrifugal fans, allowing for more efficient system operation.

Unlike traditional damper systems that restrict airflow post-fan, industrial inlet vane dampers for HVAC systems work by adjusting the angle of the incoming air. This reduces the load on the fan itself, cutting energy consumption considerably. For large-scale industrial facilities, this efficiency gain translates to substantial cost savings over time.

Another benefit is precise modulation. Inlet vane dampers offer enhanced control over airflow rates, making them ideal for maintaining balanced environmental conditions within sensitive production areas like clean rooms, laboratories, or server rooms. Consistent temperature and humidity levels are essential in such environments, and inlet vane dampers make that possible through their responsive airflow adjustment.

They also integrate seamlessly with building automation and control systems, allowing real-time monitoring and adjustments. This leads to improved operational flexibility and reduced manual intervention.

Furthermore, inlet vane dampers reduce mechanical stress on fan components by preventing system overloads. This results in longer equipment life and lower maintenance frequency, making them a smart investment for industrial HVAC systems.

Industries such as manufacturing, pharmaceuticals, and data centers benefit greatly from these energy-efficient solutions. In the long run, adopting inlet vane dampers helps companies achieve energy compliance standards and meet sustainability goals.

Freture Techno Pvt. Ltd. is a leading manufacturer of inlet vane dampers in Mumbai, India, offering robust and customizable solutions to meet diverse industrial requirements.

No comments:

Post a Comment