Damper Valves in Waste Management and Incineration Plants

In the waste management and incineration industry, damper valves are essential for controlling airflow, managing combustion, and reducing emissions. These valves ensure that facilities operate safely and comply with environmental standards while maximizing energy recovery from waste materials.

Importance of Damper Valves in Waste Processing

Waste-to-energy (WTE) incinerators and hazardous waste treatment plants rely on a controlled combustion process. Damper valves help regulate the flow of air into furnaces and manage exhaust gases passing through filters and scrubbers. By adjusting the amount and direction of airflow, they help maintain combustion efficiency and minimize the release of harmful substances.

Modern waste incineration systems often include energy recovery units, where damper valves play a crucial role in managing steam and flue gas flows. Proper regulation ensures optimal thermal efficiency and protects sensitive equipment from damage due to pressure fluctuations or backflow.

Common Types of Damper Valves Used

Louver Dampers: Provide precise modulation of airflow in ducts leading to furnaces and scrubbers.

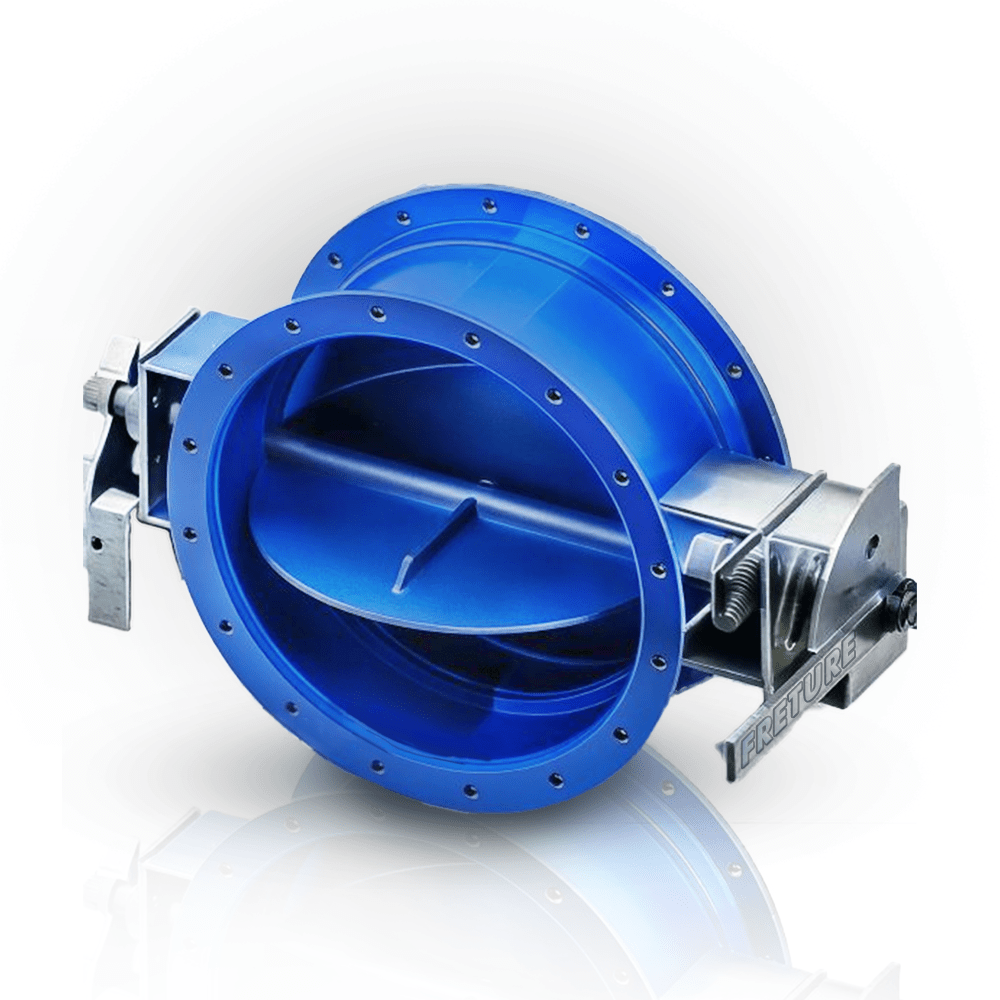

Butterfly Dampers: Compact, quick-acting valves used in moderate-pressure applications.

Guillotine Dampers: Allow full isolation of ducts during maintenance or system shutdown.

Diverter Dampers: Redirect exhaust gases between recovery units and bypass stacks.

Materials must withstand high temperatures, corrosive gases, and particulate matter—typically requiring stainless steel or special alloys for durability.

|

| Damper Valves manufacturer in Mumbai |

Applications in Waste Facilities

Municipal Waste Incinerators: Control combustion air and flue gas paths to enhance efficiency and reduce pollutants.

Hazardous Waste Facilities: Ensure sealed and safe airflow to prevent the spread of toxic fumes.

Medical Waste Treatment: Manage airflow in high-temperature incineration of biohazardous materials.

Landfill Gas Recovery Units: Use dampers to control the flow of methane-rich gases for flaring or energy production.

Benefits for the Waste Management Industry

Emission Control: Enable precise routing of flue gases through filters and scrubbers, reducing harmful emissions.

Energy Efficiency: Facilitate heat recovery by controlling the flow of hot gases to steam generators.

System Safety: Allow isolation of systems for maintenance, preventing gas leaks and backpressure.

Operational Flexibility: Adapt to varying waste loads and moisture levels with responsive airflow regulation.

Regulatory Compliance and Maintenance

Facilities must meet strict environmental regulations such as those by the EPA, EU Industrial Emissions Directive (IED), and local air quality boards. Damper valves must be engineered to comply with these rules and operate reliably in demanding environments.

Routine inspection, cleaning, and actuator calibration are essential maintenance tasks. Damaged seals or fouled blades can compromise performance, increase emissions, and trigger regulatory non-compliance.

Conclusion

Damper valves are indispensable in waste management and incineration facilities. Their role in combustion control, emission management, and energy optimization makes them vital to efficient, safe, and environmentally responsible operations.

Choosing the right Damper valve for waste processing? Work with a manufacturer that offers corrosion-resistant, high-temperature solutions tailored to the specific demands of waste incineration and treatment systems.

No comments:

Post a Comment