Across industries that rely on controlled airflow—HVAC plants, manufacturing units, power stations, chemical facilities, and ventilation systems—operational efficiency depends heavily on one core component: the damper valve. Despite being compact and often underestimated, damper valves solve fundamental airflow issues that directly affect productivity, safety, and energy consumption.

Understanding Industry Pain Points

One of the biggest challenges in large industrial systems is airflow imbalance. Without proper control, air distribution becomes inconsistent, causing hot zones, pressure fluctuations, and inefficiency in heating or cooling systems. This leads to energy wastage, discomfort, and unstable operating conditions.

Another recurring issue is air leakage caused by poorly designed or worn-out equipment. Leakage increases the load on fans and blowers, ultimately raising energy costs. In power plants and chemical industries, uncontrolled airflow can compromise safety, process integrity, and environmental compliance.

Industries also struggle with high maintenance requirements. Traditional airflow equipment requires frequent manual adjustments, lubrication, and part replacement. This not only increases downtime but also affects the operational reliability of the entire plant.

How Damper Valves Address These Problems

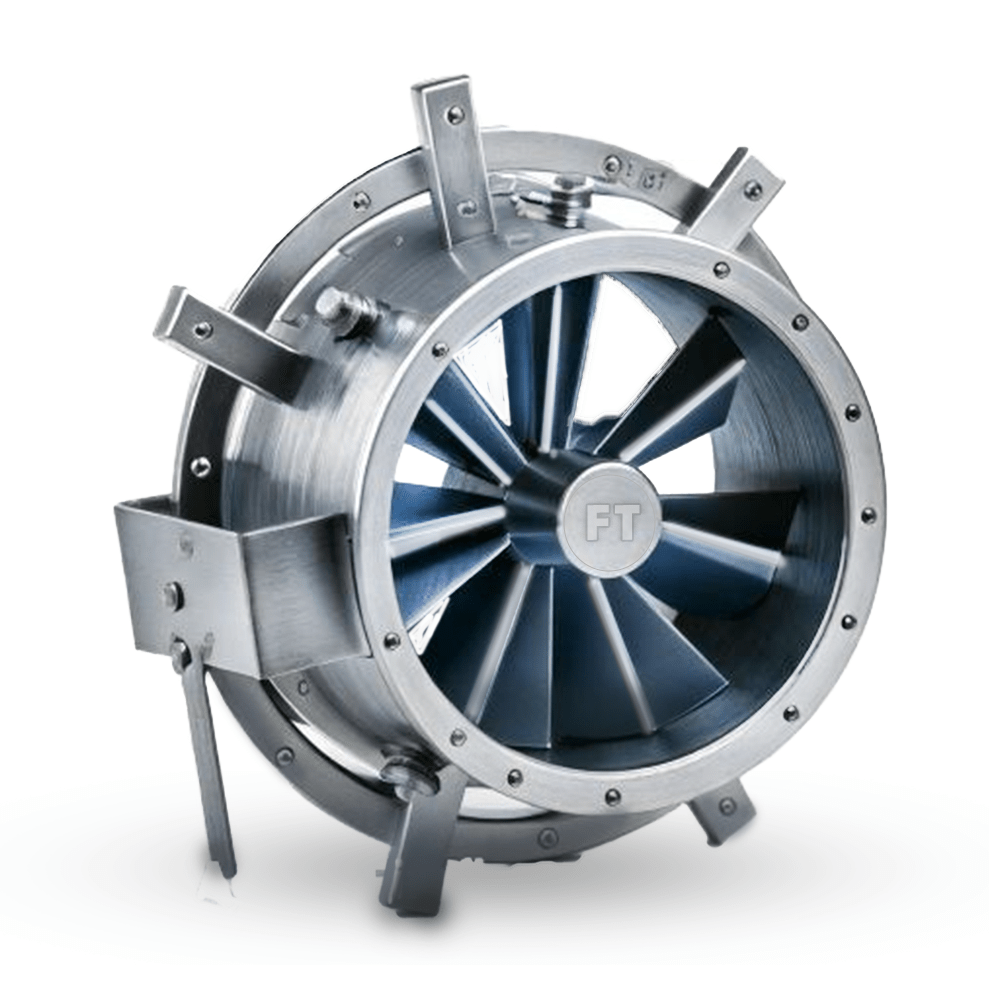

Damper valves were introduced as a direct response to the need for precise airflow management. With their adjustable blades and robust construction, they allow operators to fine-tune airflow across complex systems.

The biggest advantage is accurate airflow regulation, ensuring consistent performance even under fluctuating operating conditions. By allowing controlled opening and closing, damper valves reduce unnecessary strain on fans and compressors, lowering energy consumption.

Their tight shutoff capability significantly reduces leakage. This not only improves efficiency but also enhances safety—particularly in systems handling hot air, fumes, or hazardous gases.

From a maintenance perspective, modern damper valves require minimal intervention. The improved design allows longer operational cycles, reducing shutdowns and lowering lifetime operating costs.

Impact of Damper Valves on Modern Industrial Operations

The introduction of advanced damper valves changed how industries manage air handling systems. With better materials, improved sealing mechanisms, and automation-friendly designs, damper valves have become essential in energy optimization strategies.

Advanced control systems now allow damper valves to integrate with Building Management Systems (BMS) and SCADA platforms. This digital shift ensures real-time monitoring, automated adjustments, and predictive maintenance—further enhancing plant performance.

The environmental impact is notable too. By optimizing airflow and reducing energy waste, industries achieve better sustainability scores and comply with global energy-efficiency standards.

Conclusion

Damper valves have evolved into a crucial component for industries that depend on accurate airflow control. By solving long-standing challenges such as leakage, inefficiency, and safety risks, they have made a profound impact on operational excellence.

Freture Techno Pvt. Ltd. is a leading Damper Valves manufacturer in Mumbai, India.